Are your projects frequently experiencing disarray, despite your diligent use of tools and adherence to deadlines? You are not alone in this challenge. Managing multiple projects can quickly become overwhelming. However, what if you could establish order amidst the chaos and achieve consistent, measurable outcomes? This article delves into Six Sigma project management, a structured, data-driven approach designed to assist you in accomplishing just that.

You will learn how the Six Sigma methodology can help minimize waste, reduce unnecessary rework, and ensure your entire team remains aligned. From grasping the fundamentals of Six Sigma to examining key methodologies such as DMAIC, we will cover all the essential information you need to get your projects back on track for tangible results.

What Is Six Sigma in Project Management?

Six Sigma project management is a data-driven approach focused on eliminating waste, reducing variability, and fostering continuous improvement. It relies on defined processes, measurable outcomes, and a culture of accountability. Let’s delve deeper into its origins and evolution.

Origin and Evolution of Six Sigma

Six Sigma emerged from the pursuit of perfection. In the 1980s, Motorola sought to enhance its attention to detail and reduce defects. Engineer Bill Smith developed the Six Sigma method—a rigorous, fact-based strategy aimed at minimizing process variation. The term “Six Sigma” refers to a statistical principle indicating that a process should have only 3.4 defects per million opportunities, essentially achieving perfection.

The concept quickly gained traction, with General Electric famously adopting it in the 1990s under CEO Jack Welch, resulting in an estimated $12 billion in savings over five years. Today, Six Sigma is not limited to manufacturing; it is widely used in finance, IT, healthcare, logistics, and education. Its systematic, data-driven approach provides clarity, control, and measurable results.

Whether you are leading a Six Sigma project or supporting one, this methodology brings order to chaos, allowing teams to focus on what truly matters: delivering value to customers.

Six Sigma vs. Lean Six Sigma

While Six Sigma emphasizes defect reduction and consistency, Lean focuses on waste elimination and process simplification. Together, they form Lean Six Sigma, which combines efficiency with quality control. Here’s a quick comparison:

| Aspect | Six Sigma | Lean | Lean Six Sigma |

|---|---|---|---|

| Core Focus | Defect reduction | Waste elimination | Quality and speed |

| Approach | Data-driven, statistical control | Visual tools, flow optimization | Balanced use of data and speed |

| Methodology | DMAIC / DMADV | Kaizen, Value Stream Mapping | DMAIC with Lean principles |

| Origin | Motorola, 1980s | Toyota Production System, 1950s | Fusion of both (late 1990s–2000s) |

| Best For | Complex processes with high variability | Repetitive tasks with inefficiencies | Organizations needing both control and agility |

| Certification Focus | Statistical mastery | Process flow and teamwork | Cross-functional leadership |

Understanding this distinction helps you apply the right tools to the right problems, whether you’re managing a Lean Sigma project or supporting a Six Sigma initiative.

Core Six Sigma Methodologies

Every successful Six Sigma project follows a structured methodology that has been tested and refined across various industries for decades. Whether you’re in IT, manufacturing, or healthcare, knowing the right framework can be the key to success.

Six Sigma project management primarily utilizes two models: DMAIC and DMADV. These are not just buzzwords; they are systematic, step-by-step guides for addressing current inefficiencies and designing future solutions.

DMAIC Explained

DMAIC stands for Define, Measure, Analyze, Improve, and Control. This approach is ideal for improving existing processes. Each step is crucial for avoiding errors, streamlining operations, and achieving long-term results.

Define

The Define stage lays the groundwork for the entire problem-solving process. It involves clearly stating the problem, setting project goals, and outlining the scope of work. For instance, in a Six Sigma IT project, this might mean identifying frequent system downtimes that impact user satisfaction.

Measure

In this stage, data collection takes center stage. Teams establish baselines and assess process capabilities using metrics like cycle time, defect rate, and throughput. The goal is to accurately measure the current process to gauge improvements effectively.

Understanding the “maximum opportunity six sigma definition” is vital here, as it helps teams identify potential defect opportunities within each process step, ensuring precise defect measurement and better project tracking.

Analyze

During the Analyze phase, teams employ techniques like Root Cause Analysis (5 Whys) and Fishbone Diagrams to identify the root cause of the problem. This step focuses on addressing the underlying issues rather than just the symptoms.

Improve

In the Improve stage, teams test and develop solutions. This may involve pilot testing, brainstorming sessions, or applying Kaizen methodologies to implement improvements. The aim is to achieve measurable enhancements—faster outputs, fewer errors, and higher quality.

Control

To sustain improvements, the Control phase establishes monitoring systems. Updated Standard Operating Procedures (SOPs), training programs, and control charts help maintain consistency. This is essential for achieving long-term success in Six Sigma management.

DMADV Overview

While DMAIC is used to enhance existing processes, DMADV is designed for creating new ones. The acronym stands for Define, Measure, Analyze, Design, and Verify. This strategy is applicable across various fields, including aerospace, healthcare, and IT development.

DMADV begins similarly with defining objectives and measuring key performance indicators. However, the Analyze stage focuses on understanding customer requirements and translating them into system requirements. The Design stage involves creating blueprints or prototypes, followed by the Verify stage, which tests whether the new solution meets goals and customer needs.

Together, DMAIC and DMADV provide the flexibility needed for Lean Six Sigma projects, allowing teams to either improve existing processes or develop new ones. This adaptability is why they form the foundation of modern Six Sigma project methodology: precise, actionable, and universally applicable.

Six Sigma in Project Management

Six Sigma is no longer confined to manufacturing; it is now prevalent in various sectors, including IT, software development, engineering, healthcare, and finance.

Whether you lead a small team or manage multiple departments, Six Sigma project management brings order, transparency, and accountability to what can easily become chaotic.

Applying Six Sigma to IT and Engineering Projects

It is a common misconception that Six Sigma is applicable only to physical production. However, digital environments frequently encounter hidden inefficiencies, such as slow systems, unclear requirements, and costly rework. This is why many organizations are adopting Six Sigma principles to streamline processes, including cloud migration and app development.

In the IT sector, the Define and Measure stages focus on identifying user pain points and gaps in system performance. The Analyze phase can uncover bottlenecks in software delivery pipelines, while the Improve phase may focus on refining deployment processes. In engineering, Six Sigma promotes tighter quality control, optimized resource utilization, and enhanced risk management.

Companies such as IBM, Dell, and Siemens serve as examples of successful Six Sigma implementation in IT. They have utilized Six Sigma management to reduce downtime, enhance system security, and accelerate project timelines. The key to their success lies in making data-driven decisions, thereby eliminating guesswork.

Project Selection and Scoping

Not every project requires a full Six Sigma overhaul. Careful selection and scoping are essential. A good Six Sigma project typically:

- Addresses a recurring, high-impact problem

- Produces measurable outcomes

- Can be completed within 3–6 months

- Aligns with strategic business goals

Teams often use criteria like impact vs. effort matrices, customer complaints, and defect reports to identify the right initiatives. In Lean Six Sigma project management, scoping is crucial; attempting to tackle too much at once can dilute focus.

The scoping phase also identifies stakeholders, defines timelines, and clarifies deliverables, ensuring alignment before execution begins.

Six Sigma vs. Agile in Project Environments

Many teams wonder: Can Six Sigma be integrated into Agile environments? The answer is yes—with the right balance. While Agile emphasizes flexibility and speed, Six Sigma provides control and data-driven decision-making. When combined effectively, they complement each other.

Think of Agile as the engine driving sprints and Six Sigma as the steering system guiding those efforts. For example, Six Sigma tools like Root Cause Analysis, defect tracking, and Value Stream Mapping can be incorporated into Agile sprints to enhance backlog quality and reduce bugs.

In today’s hybrid project environments, integrating Lean Six Sigma with Agile project management leads to faster delivery, fewer defects, and improved user outcomes.

Essential Six Sigma Tools and Techniques

Mastering Six Sigma involves more than just understanding theory; it requires applying the right tools to tackle complex problems. These tools help structure your processes, clarify your data, and drive improvements.

Whether you’re overseeing an IT rollout, engineering workflows, or managing a cross-functional team, these techniques are vital for every Six Sigma project.

SIPOC Diagram

The SIPOC diagram acts as a project blueprint. SIPOC stands for Suppliers, Inputs, Process, Outputs, and Customers. This tool is often used during the Define phase of the DMAIC framework, allowing teams to see all parts of a process at a glance.

For example, when an application team is launching a new feature, they can use the SIPOC diagram to identify where the information comes from (Suppliers), what inputs are being used (Inputs), the entire process, and who the final recipients are (Customers). This approach helps ensure that no important factors are missed and that all team members are on the same page from the start.

Root Cause Analysis (5 Whys)

One of the simplest yet most effective tools in Six Sigma is the 5 Whys technique. It involves asking “Why?” five times to uncover the root cause of a problem.

For instance, if a bug is causing your company’s mobile app to crash, you might ask:

- Why did it crash? Due to a null pointer error.

- Why was that error unhandled? Because the automated test missed it.

- Why didn’t the test catch it? Because the test case didn’t cover that scenario.

- Why wasn’t that scenario included? Because the QA team rushed testing due to tight deadlines.

- Why were the deadlines so tight? Because there was no buffer in the sprint schedule for late-stage QA.

This technique is powerful because it goes beyond symptoms to identify the underlying issues. It is often used in manufacturing to prevent recurring mistakes.

Value Stream Mapping

Value Stream Mapping (VSM) provides a visual representation of the flow of value within a process, from beginning to end. It identifies delays, redundancies, and activities that do not add value, facilitating the detection of waste.

In the context of a Lean Six Sigma project, employing Value Stream Mapping assists in identifying handoff delays, approval bottlenecks, and excess inventory. The result is improved workflows and faster delivery.

Kaizen and Continuous Improvement

Kaizen, which means “change for the better,” is at the heart of Lean Six Sigma thinking. Instead of waiting for major changes, Kaizen encourages ongoing small improvements. Teams hold Kaizen events to quickly identify, implement, and standardize enhancements, fostering a culture of quality among all team members, from interns to executives.

Poka-Yoke (Error Proofing)

Poka-Yoke, a Japanese term for mistake-proofing, involves creating processes that make errors nearly impossible. In manufacturing, this could mean a fixture that only fits one way. In IT, it might involve a form that flags invalid inputs before submission.

When applied effectively, Poka-Yoke reduces defects, minimizes the need for employee training, and decreases rework—key principles of solid Six Sigma management.

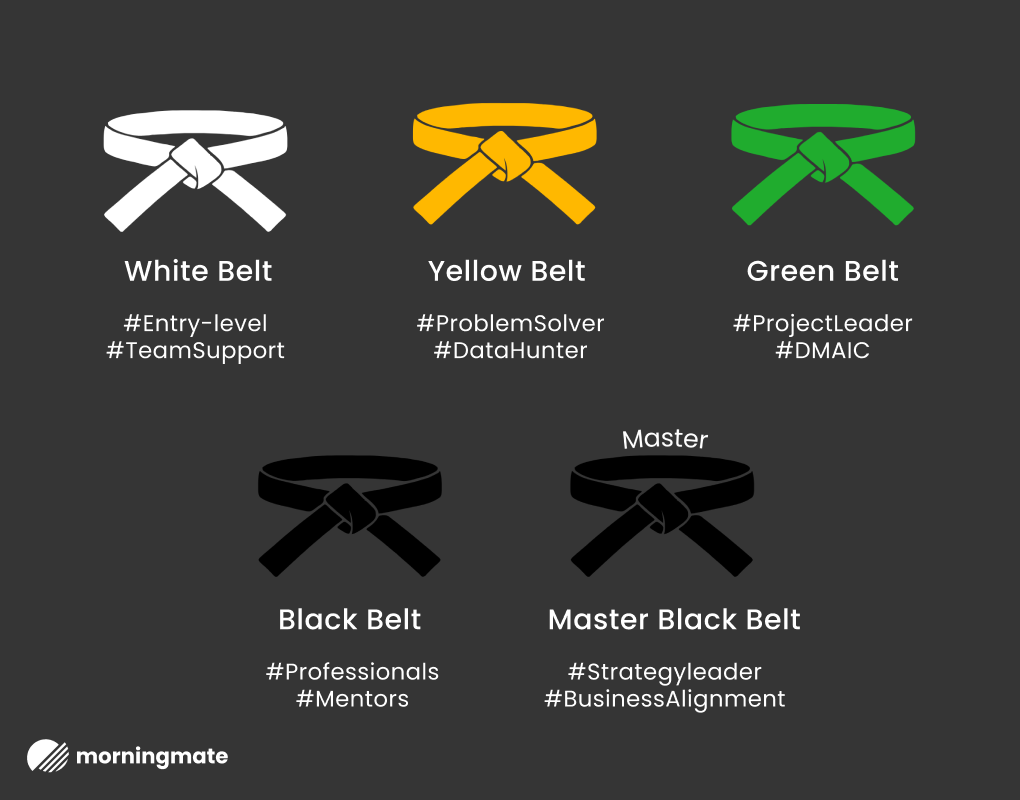

Lean Six Sigma Belt Levels and Roles

Lean Six Sigma operates similarly to martial arts, where mastering process improvement requires discipline and practice.

Professionals are classified by “belt” levels, each indicating their knowledge, leadership role, and contribution to a Lean Six Sigma project.

White, Yellow, Green, Black, and Master Black Belts

Here’s a breakdown of the belt levels:

- White Belt: Entry-level. White Belts have a basic understanding of Six Sigma principles and can participate in local improvement teams. They may not be deeply involved in statistics or tools, but they know the terminology.

- Yellow Belt: These team members support Six Sigma projects by collecting data, mapping processes, or identifying waste. They understand tools like SIPOC and 5 Whys and are valuable contributors.

- Green Belt: Often the backbone of a Six Sigma project, Green Belts lead smaller initiatives or assist Black Belts with larger ones. They are trained in DMAIC, root cause analysis, and statistical process control.

- Black Belt: These professionals lead complex, cross-functional Lean Six Sigma projects. They manage teams, mentor Green Belts, and utilize advanced statistical tools. Many organizations view Black Belts as full-time change agents.

- Master Black Belt: The highest level. Master Black Belts not only manage projects but also develop Six Sigma strategies. They coach others, align programs with business objectives, and often report to senior leadership.

Each level plays a specific role, ensuring that Six Sigma project management is collaborative, accountable, and scalable.

Role of a Six Sigma Project Manager

A Six Sigma project manager wears many hats: coach, analyst, problem solver, and strategist. They guide the team through the DMAIC steps, monitor project metrics, ensure timely outputs, and communicate with stakeholders.

Unlike traditional project managers, they rely heavily on data. They use control charts instead of intuition and root cause analysis tools rather than assumptions. Whether managing a supply chain optimization project or a Six Sigma IT initiative, they focus on achieving sustainable, measurable outcomes—not just completing tasks.

Certification Paths for Six Sigma Professionals

Obtaining Six Sigma certification not only enhances your resume but also helps you become a more data-driven, results-oriented leader. Among the most sought-after certifications, Green Belt and Black Belt are key milestones in your Six Sigma career.

Green Belt vs. Black Belt

A Green Belt is suitable for professionals who want to lead smaller projects or support larger ones. You’ll learn essential tools, the DMAIC framework, and how to apply them in real-world business scenarios. Most Green Belts balance project work with their regular roles, making it a flexible entry point into Six Sigma project execution.

In contrast, a Black Belt is more advanced. You’ll take full ownership of projects, lead teams, and conduct in-depth statistical analysis. Black Belts often mentor Green Belts and participate in strategic decisions that affect multiple departments. For those looking to specialize in Six Sigma management or transition into continuous improvement leadership roles, Black Belt certification is the next logical step.

Online Courses and Programs

With the rise of online education, becoming Six Sigma certified is more accessible than ever. Organizations like ASQ, Coursera, Simplilearn, and GoLeanSixSigma offer comprehensive programs at all belt levels. These programs include case studies, quizzes, project work, and teaching assistance.

Many professionals choose online certification because it allows them to apply what they learn immediately, improving processes at work while completing their courses. The convenience and global recognition make it a worthwhile investment for those committed to mastering Six Sigma methodology.

Benefits of Using Six Sigma for Project Success

At its core, Six Sigma project management aims to achieve better results with fewer errors. This is why companies worldwide—ranging from Fortune 500 firms to fast-growing startups—adopt it as their long-term strategy for excellence.

Reduced Defects and Rework

By utilizing techniques like Value Stream Mapping, Poka-Yoke, and Root Cause Analysis, teams significantly reduce the chances of repeating mistakes. The benefits include less waste, fewer defects, and shorter repair times. For businesses managing multiple projects, these improvements can scale rapidly.

Improved Stakeholder Satisfaction

Clear timelines, fewer surprises, and measurable progress are what stakeholders experience when you run a Six Sigma project. With everything backed by data and tracked through DMAIC phases, communication becomes clearer, and confidence grows. Clients, managers, and cross-functional teams are more engaged when they see results unfold in real-time.

Data-Driven Decision-Making

The most significant advantage is the shift in mindset. Six Sigma management replaces assumptions with facts. Decisions are based on data rather than gut feelings, reducing bias, aligning goals across departments, and increasing accountability. In a world where every decision can impact profit, speed, or quality, this transformation can revolutionize not just individual projects but entire organizations.

Common Pitfalls in Six Sigma Projects

Even with the best intentions, 6 sigma project management can go off track if the foundation isn’t solid. Many projects fail not because of the tools, but because of how—or why—they’re applied.

Misalignment with Business Goals

One of the biggest mistakes is choosing projects that don’t support the overall business strategy. If a Six Sigma project isn’t aligned with top-level objectives, it can drain resources and enthusiasm. Teams may complete all five phases of DMAIC only to find that the outcome didn’t matter. That’s why it’s critical to select initiatives that contribute directly to revenue, efficiency, or customer experience.

Poor Data Collection

Six Sigma relies on data, but bad data leads to bad decisions. Teams sometimes rush through the Measure phase, using incomplete, outdated, or inaccurate metrics. Without a trustworthy baseline, it becomes impossible to analyze root causes or track real improvement. That’s when 6 sigma project tracking starts to break down.

Inadequate Team Training

A Lean Six Sigma project is only as strong as the people running it. If team members don’t understand the tools or the purpose behind them, the project suffers. Training isn’t just a box to check—it’s how you empower people to solve problems methodically, not emotionally. When training is skipped or shallow, momentum fades fast.

FAQs About Six Sigma in Project Management

What Types of Projects Benefit From Six Sigma?

Any project that involves repeat processes, has measurable results, and has the potential for improvement can utilize it. Whether it’s streamlining IT system outages or increasing the speed of the production line, Six Sigma works where there is accuracy.

How Long Does a Typical Six Sigma Project Take?

On average, a 6 sigma project spans between 3 to 6 months. Some shorter initiatives can be completed in weeks, while complex ones, such as cross-functional process redesign, can last up to a year.

Can Six Sigma be Used With Agile or Scrum?

Yes. Many teams combine Six Sigma tools, such as root cause analysis and value stream mapping, with Agile frameworks. The key is to maintain Agile’s flexibility while letting Six Sigma management handle data-driven problem-solving.

Ready to Run Smarter Projects with Less Stress?

Embracing 6 Sigma project management is not only about achieving milestones—it’s about establishing cultures of clarity, efficiency, and repeated achievement. Managing several tasks, teams, and products remains overwhelming, nonetheless.

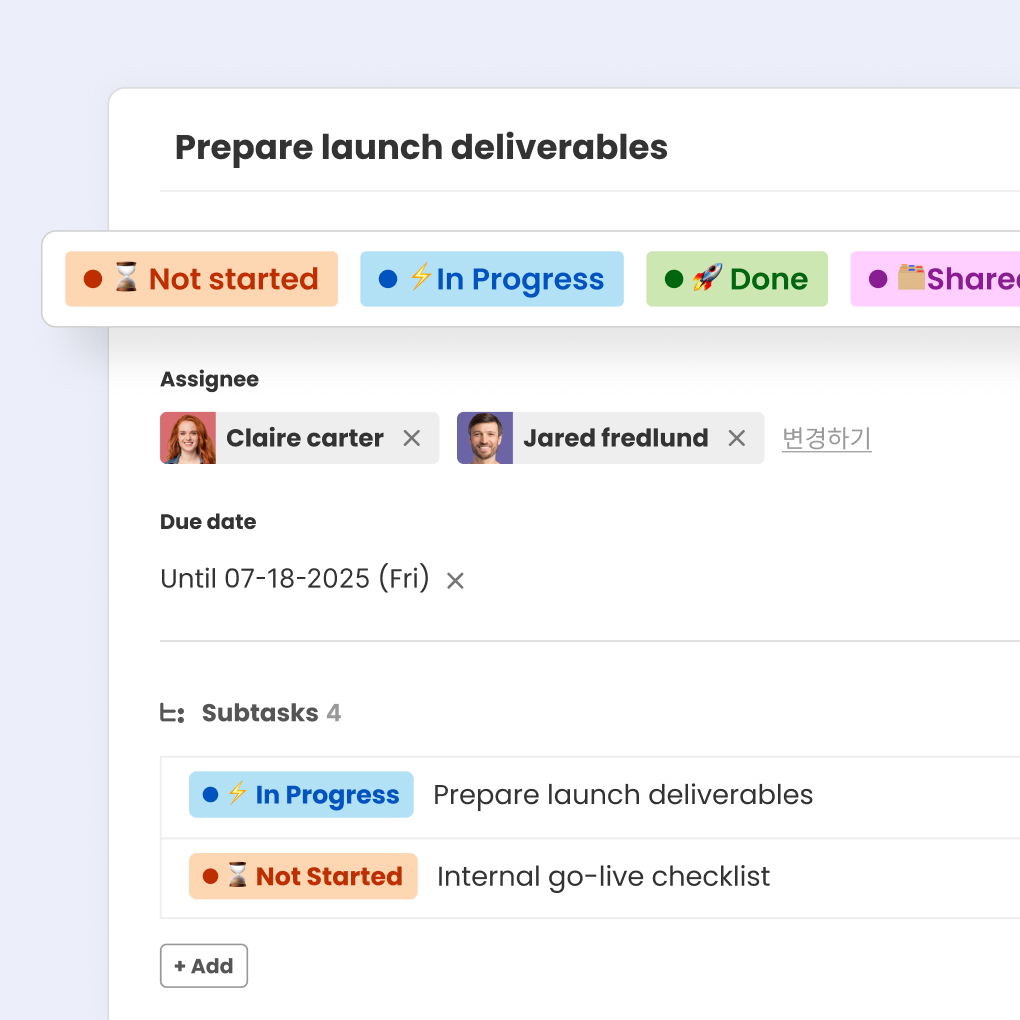

That’s where Morningmate comes to the rescue. It’s your all-in-one command hub for collaboration, project monitoring, and instant communication—minus the chaos. Whether you have your hands on the Lean 6 Sigma project, mentoring team members along the DMAIC journey, or coordinating schedules across departments, Morningmate simplifies it, makes it visual, and streamlines it.

Why choose Morningmate?

- Real-time project tracking that aligns with your Six Sigma project methodology.

- Easy-to-use dashboards for cross-functional teams.

- Built-in task and role clarity—no more follow-up confusion.

- Centralized workspace for sharing Six Sigma documents, SIPOC charts, and reports.

- Smooth onboarding even for non-technical team members.

Start your free Morningmate trial today—experience how simple smart project management can feel.